Insights

Defects are bound to occur during the reprocessing of mechanical equipment or metal parts. As a result, the final step of surface treatment holds significant importance. It serves the dual purpose of enhancing the aesthetics and protecting the surface, ultimately improving the performance of metal components and preventing rust.

2023-11-03 14:08:28

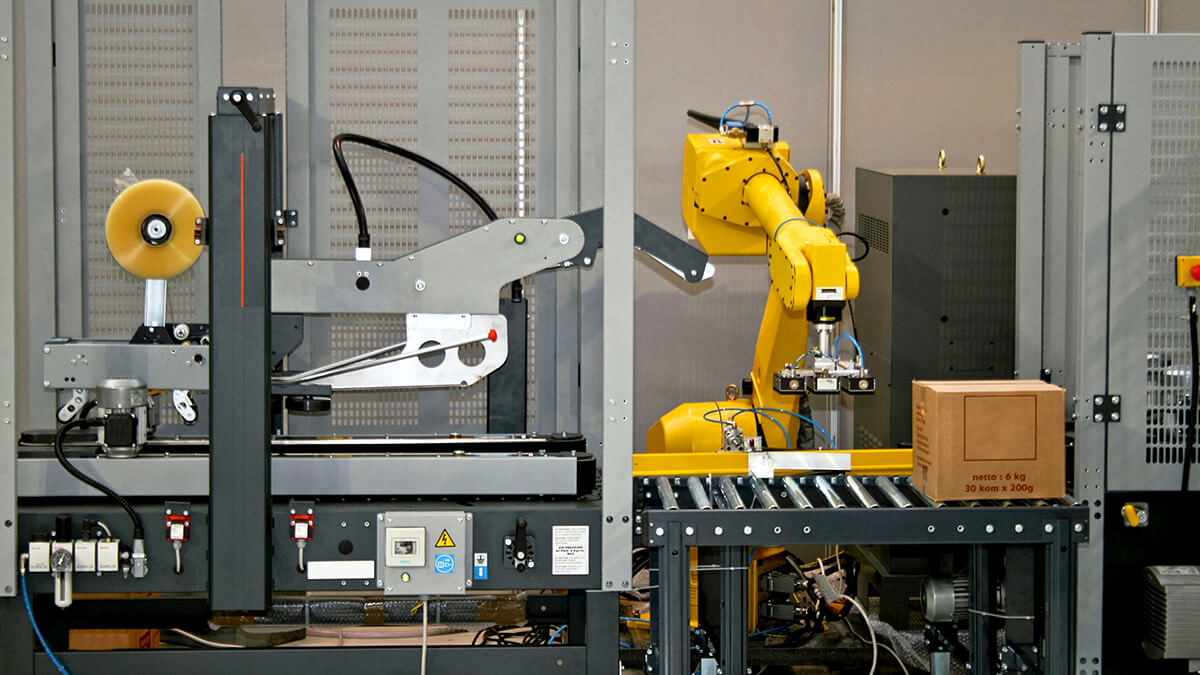

The worldwide manufacturing sector is shifting toward smart manufacturing, with Industry 4.0 leading the way by promoting greater efficiency, reduced costs, and intelligent, adaptable production processes. The nine key technologies of Industry 4.0 encompass Big Data, Layered Manufacturing, Cloud Technology, Automation, System Integration, Internet of Things, Cybersecurity, Augmented Reality, and Simulation.

2023-11-03 13:57:30

In most cases, blackening treatment on steel, also known as black oxidation, can enhance corrosion resistance to a certain extent. However, the protective effect remains somewhat limited. To significantly improve both corrosion resistance and lubrication of the blackened layer, additional measures like oil immersion or subsequent rust prevention treatment are still necessary.

2023-11-03 13:33:55

Anodization is a surface treatment process, typically performed as the final step in metal manufacturing. It is a dependable and cost-effective method for enhancing wear resistance and adding color to precision machined metal parts, particularly aluminum and other non-ferrous metals.

2023-11-03 13:25:22

Are you familiar with the latest terminology related to Tooling 4.0? In this article, we'll offer an overview and examples that can help manufacturers understand and align with this evolving concept. Tooling 4.0 revolves around leveraging technology to transform 'inefficient' products into 'intelligent' ones.

2023-10-27 10:42:06

In the present day, conventional industries are blending Internet of Things technology to drive the evolution of Industry 4.0 and the advancement of smart manufacturing.

2023-10-27 10:30:52

In recent years, plastic electroplating has been widely used in decorative electroplating of plastic parts. ABS plastic is the most widely used kind of plastic electroplating.

2023-10-12 14:30:04

Metal stamping refers to the use of the power of punching machinery and the use of molds as metal plate forming tools to produce punching separation or plastic deformation effects to achieve the production technology of parts in terms of size, shape, and performance requirements.

2023-10-12 14:20:48

The advantage of the gearbox is that it can accurately control the speed of the main shaft without excessively high main shaft speed, belt friction consumption, and slippage. Because the main shaft is placed horizontally, it is also called a horizontal lathe.

2023-10-12 13:49:05

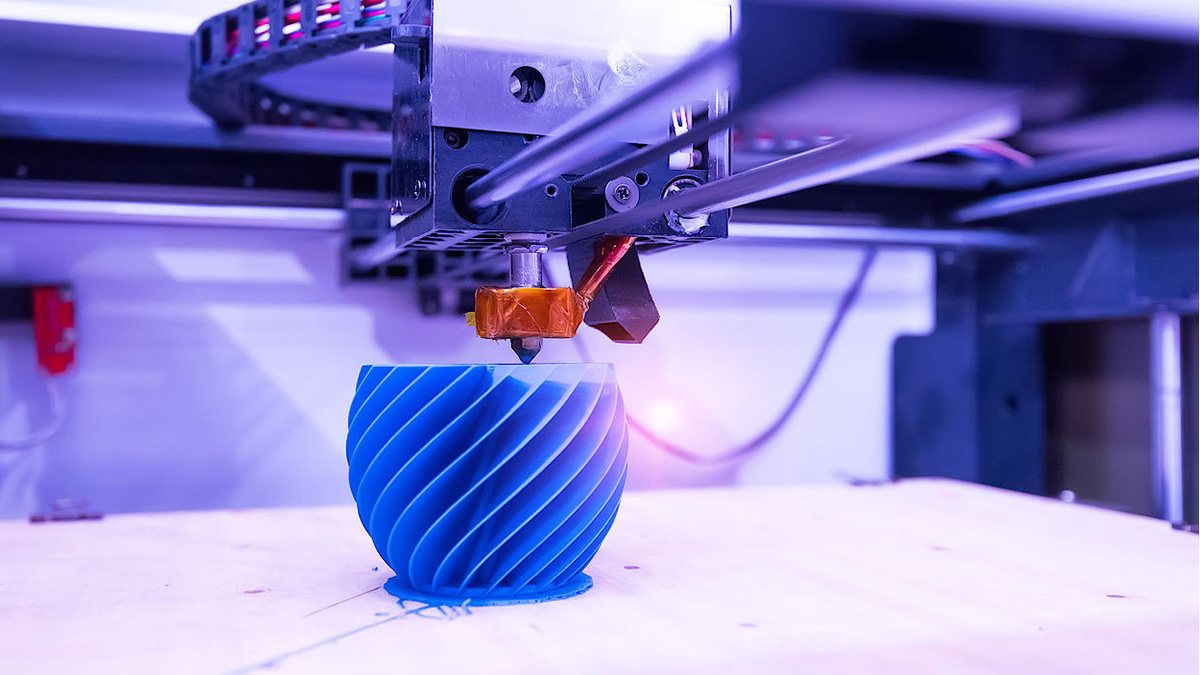

Additive manufacturing is playing an increasingly important role in the manufacturing industry and is mainly used in toolmaking and prototype construction.

2023-10-12 13:43:06

Hot Topic

Agree