SISTER MACHINE TECHNOLOGY CO., LTD., founded in October 2006 in Taiwan, has swiftly become a leader in the design and manufacturing of advanced, high speed machining centers. SISTER specializes in double column high-speed machine centers, double column high-speed graphite machine centers, double column (gantry type) high-speed machine centers, and vertical machine centers. Each of these products embodies the company's commitment to high-speed cutting, high quality, express service, and a customer-first approach. SISTER MACHINE TECHNOLOGY’s high-speed cutting solutions cater to a broad spectrum of industrial applications, from automotive and aerospace manufacturing to intricate mold making and part production.

Importance of High-Speed Machine Centers

High-speed machine centers offer several significant advantages over standard machine centers, making them increasingly important in modern manufacturing environments where efficiency, precision, and productivity are important. Advantages include:

Increased Productivity: Operating at much higher spindle speeds and feed rates compared to standard machine centers, allows for faster material removal rates, which significantly reduces cycle times, boosting overall productivity.

Improved Surface Finish: High-speed cutting reduces the heat generated at the cutting zone, resulting in less thermal distortion, better surface finishes, and better surface integrity.

Greater Precision: High-speed machine centers often incorporate advanced motion control technologies and high-precision spindles. These features allow for tighter tolerances and better repeatability, which is essential for industries requiring high levels of precision, such as aerospace and medical device manufacturing.

Reduced Tool Wear: Despite operating at higher speeds, high-speed machine centers can actually reduce tool wear in some scenarios. The high speeds help to distribute the heat generated during the machining process more efficiently, which prevents excessive wear and extends tool life.

Enhanced Capabilities for Complex Parts: Advanced capabilities such as 5-axis machining enables manufacturers to produce intricate parts with complex geometries in a single setup, reducing the need for multiple setups and handling, thereby reducing potential errors.

Energy Efficiency: Faster machining speeds mean shorter production times per piece, which can lead to reduced energy consumption per part produced.

Flexibility and Competitiveness: High-speed machining centers provide the flexibility to adapt to various production demands and material types, allowing companies to respond swiftly to market changes and customer needs.

Decreased Non-Cutting Time: High-speed centers often feature rapid tool change systems and quicker positioning speeds, which reduce the non-cutting time associated with tool changes, machine setups, and part loading/unloading.

Types of High-Speed Machine Centers

There are various types of high-speed machine centers, each offering unique advantages. Understanding the unique qualities of each type can help in making the best choice of machining center for your manufacturing needs.

Double Column High-Speed Machine Centers

Double Column High-Speed Machine Centers are CNC (Computer Numerical Control) machining centers characterized by their distinctive double column design. This design provides greater space between the two columns, offering enhanced rigidity and support for machining large workpieces with better accuracy compared to single-column designs.

Equipped with high-speed spindles that can handle a wide range of speeds, typically from 10,000 to 25,000 RPM or more, these centers efficiently machine complex parts with fine details and smooth finishes. Advanced control systems with 3, 4, or even 5-axis capabilities offer high precision and control in the machining process, eliminating the need to reposition the workpiece.

These machines often integrate easily with robotic systems and other forms of automation, enhancing productivity and reducing labor costs. Many double column machines are designed with thermal compensation technologies to manage heat effects and maintain precision.

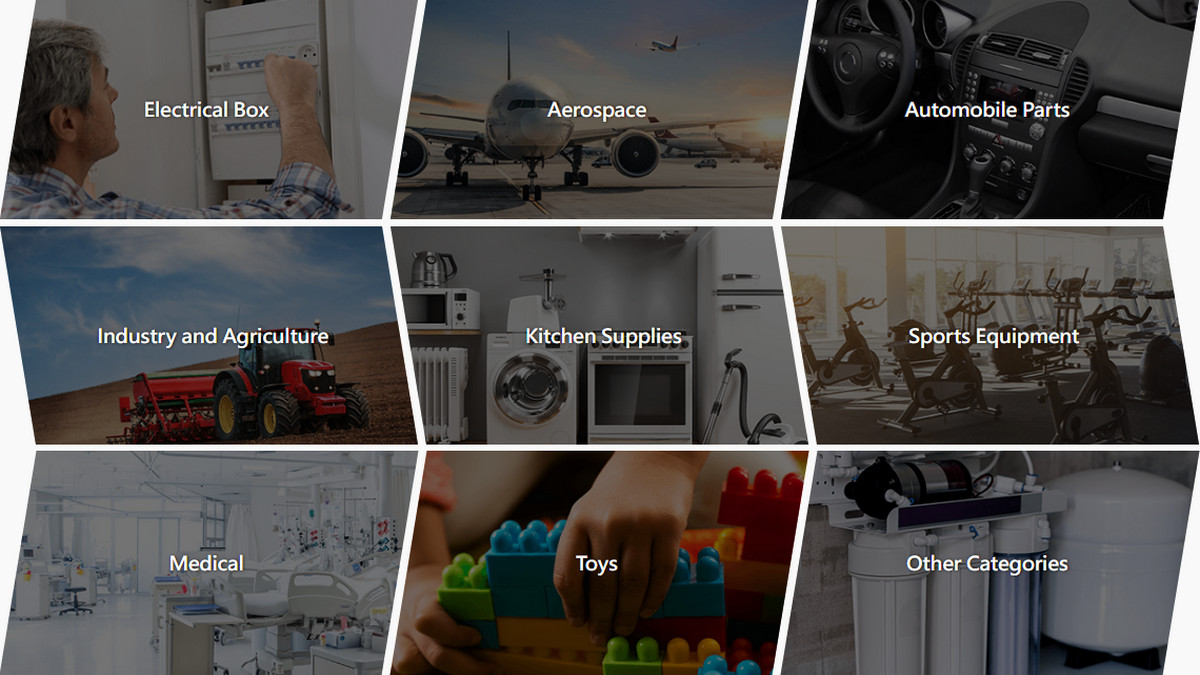

These features make Double Column High-Speed Machine Centers ideal for applications such as aerospace components, automotive parts, mold and die making, and general machining, where rapid material removal and tight tolerances are essential.

Double Column High-Speed Graphite Machine Centers

A Double Column High-Speed Graphite Machine Center is a specialized type of CNC machining center designed primarily for the precision machining of graphite and other similar materials. Graphite machining is crucial in industries such as electronics manufacturing (for EDM electrodes), automotive (for molds and dies), and aerospace.

Like other double column machines, this design provides excellent rigidity and stability, minimizing vibration during the machining process, which is vital for achieving high precision in graphite parts.

Graphite is notorious for creating fine dust during machining, which can be hazardous to health and can also interfere with machine operation. These machine centers are equipped with sophisticated dust extraction and management systems to keep the working environment clean and safe.

Graphite machining centers often incorporate advanced thermal stability features to control thermal expansion. This is important because even small temperature changes can significantly affect the dimensions and tolerances of graphite parts.

Gantry Type High-Speed Machine Centers

Gantry Type High-Speed Machine Centers employ a bridge-like frame that spans over the work area, with the cutting tool attached to a carriage that moves along the bridge. This setup provides excellent rigidity and stability, reducing vibrations during machining, which is crucial for high precision work.

The open design allows for a large work envelope, making it ideal for machining large or long parts, such as aerospace components or large molds. Many gantry type centers feature 3-axis, 4-axis, or even 5-axis capabilities. Like other advanced machine centers, gantry types can be integrated with robotic systems and other automated material handling solutions to further increase productivity and reduce manual labor.

Gantry Type High-Speed Machine Centers are particularly useful in sectors like aerospace, automotive, and large-scale industrial manufacturing, such as shipbuilding, construction equipment manufacturing, and large-scale machining of components.

Vertical Machine Centers

The most defining feature of Vertical Machine Centers (VMC) is the vertical orientation of the spindle. This orientation provides several advantages, making the VMC suitable for a variety of machining tasks, particularly milling, drilling, and tapping. It allows gravity to assist in removing chips from the workpiece, reducing the risk of re-cutting chips, which can damage the surface of the part and wear out tools more quickly.

Compared to horizontal machining centers, vertical centers generally have a smaller footprint relative to their work envelope. This makes them an ideal choice for shops with limited floor space. In a VMC, the tool drops down into the material, and this vertical orientation of the spindle provides straightforward access to the workpiece. It allows for the use of shorter, more rigid tooling and facilitates easy tool changes, making setup quicker and simpler.

Modern VMCs are equipped with advanced CNC controls that support additional features like automatic tool changers (ATCs), pallet changers, and advanced programming capabilities, which can further enhance productivity.

Vertical machine centers come in various sizes and capabilities, from small benchtop models to large machines capable of handling massive parts. They are typically less expensive than their horizontal counterparts, both in terms of initial investment and maintenance costs. VMCs are incredibly versatile and can handle a wide range of materials and operations, making them a popular choice among small to medium-sized enterprises.

Looking Ahead with SISTER MACHINE TECHNOLOGY

SISTER's specialization in high-speed cutting technologies ensures that their machine centers are optimized for rapid and precise machining operations. As SISTER Machine Technology Co., Ltd. continues to grow and innovate, their reputation for high-quality manufacturing, personalized solutions, fast responsive technical support, and timely maintenance services assures they will meet each client's unique precision machining needs.

Whether through the robustness of their double column centers, the precision of their graphite machining centers, the stability of their gantry type centers, or the versatility of their vertical centers, SISTER Machine Technology ensures that each client’s manufacturing capabilities translate into tangible value and a competitive advantage.