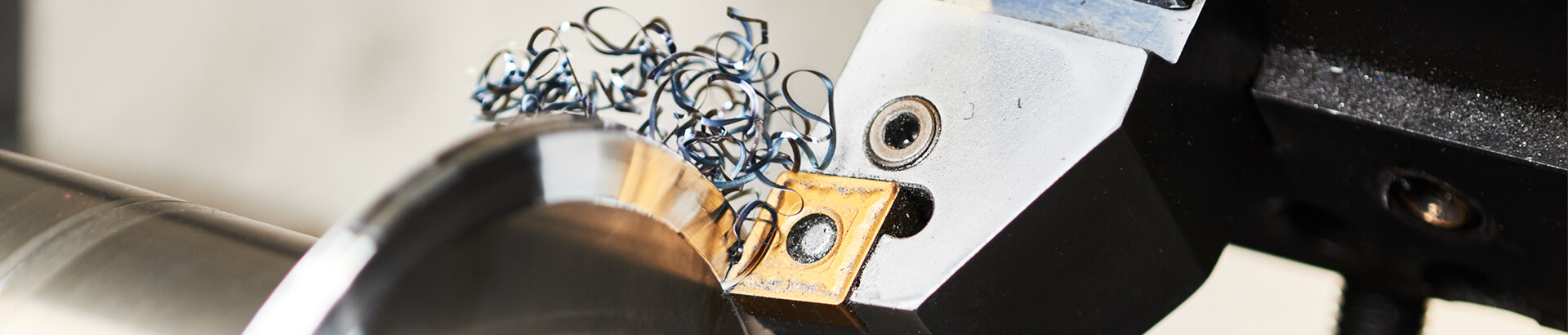

In the cutting of hardware components, a comprehensive analysis of factors is required, and through strict process flow, a suitable cutting process can be planned to manufacture hardware components of stable quality.

How to Choose the Machine Tool Equipment for Manufacturing Hardware Parts?

There are generally two situations when manufacturing parts on a CNC machine tool. The first case: there are a part pattern and a blank, and the CNC machine tool suitable for the part should be selected. The second case: There is already a CNC machine tool, and the parts suitable for the machine tool must be selected. In either case, the main factors to be considered are the material and part contour complexity of the semi-finished product, size, accuracy, number of parts, heat treatment requirements, etc.

The following describes how to select machine tool equipment:

-

Determination of the CNC process method

- Selection of process method: The selection principle of the process method is to ensure the requirements of surface accuracy and roughness. Since there are generally many methods to obtain the same level of accuracy, in the actual selection, the shape, size, and heat treatment requirements of the parts must be fully considered.

- Principles of plan determination: The craftsmanship of the more precise surface on the parts is often gradually achieved through rough work, semi-precision, and precision. It is not enough to select the corresponding final method based on the quality requirements for these surfaces. The plan from semi-finished product to final shape should be correctly determined. When determining the plan, first, according to the requirements of the accuracy of the main surface and the surface roughness, the method required to meet these requirements should be initially determined.

-

Selection of CNC machine tools

- Use of lathe: A lathe is a machine tool that mainly uses a turning tool to turn a rotating workpiece. Lathes are mainly used for processing various rotating surfaces and the end faces of rotating bodies. Such as turning inner and outer cylindrical surfaces, conical surfaces, ring grooves and forming revolving surfaces, turning end faces and various commonly used threads, and processing various special-shaped surfaces with process equipment. Drills, reamers, reamers, taps, dies and knurling tools can also be used on the lathe for corresponding processing.

- Use of milling machine: A milling machine is a machine tool with a wide range of uses. On the milling machine, it can process planes, grooves, surfaces of parts with teeth, and various curved surfaces. Besides, it can also be used to process and cut the surface of the revolving body and the inner hole. The workpiece of the milling machine is mounted on the operating table or the indexing head and other accessories. The main motion of the milling cutter is rotated and the feed motion of the operating table or the milling head is supplemented, and the workpiece can obtain the required workpiece surface. Due to the multi-cut intermittent cutting, the efficiency rate of the milling machine is higher.

- The use of slotting: Slotting machines are mainly used for processing various flat and linear forming surfaces. If equipped with a profiling device, it can also process spatial curved surfaces, such as turbine impellers, spiral grooves, etc. The tool structure of this type of machine tool is simple, and the efficiency is low because it does not cut during the return stroke. It is generally used for single-piece small batch processes.

- Use of boring machine: The boring machine is suitable for plane milling and hole cutting of single or small-batch parts. The end of the spindle box is designed with a flat-rotating radial tool post, which can accurately be boring larger holes and planes. Also, drilling, reaming, and thread cutting can be performed.

- Use of grinder: Grinding tools are used as tools to cut the surface of the workpiece. The machine tool is collectively called grinders. Grinders can be used on various surfaces, such as inner and outer cylindrical and conical surfaces, flat surfaces, gear tooth surfaces, spiral surfaces, and various molding surfaces. Sharpening tools and cutting, etc., the process range is very wide. Since grinding is easy to obtain high precision and good surface quality, the grinder is mainly used for the precision work of parts, especially the precision work of hardened steel parts and high hardness special materials.

- Use of drilling machine: The drilling machine is a versatile machine tool with a wide range of uses, which can drill, ream, ream, flat, and tap the parts. Boring can also be carried out when the radial drilling machine is equipped with process equipment, and the keyway can be milled with a universal console on the bench drill.

-

Selection of high-speed cutting oil

The factors that affect the accuracy of ultra-high-speed cutting generally include cutting standards, the accuracy of cutting tools, the quality of workpiece materials, and the performance of cutting oil. How to choose cutting oil is also an important issue in metal cutting technology:

- Silicon steel cutting oil: Silicon steel is a relatively easy-to-cut material. Generally, low-viscosity cutting oil is used to prevent the generation of cutting burrs for the ease of cleaning of the finished workpiece.

- Carbon steel cutting oil: When selecting carbon steel cutting oil, the best viscosity should be determined according to the difficulty of the process, the oil supply method, and the degreasing conditions. Secondly, the use of sulfur cutting oil can avoid the rust problem of the chlorine type cutting oil.

- The stainless-steel cutting oil: Stainless steel is a material that is prone to hardening, and cutting oil with high oil film strength and sintering resistance is required. Generally, cutting oils containing sulfur-chlorine compound additives are used to avoid problems such as burrs and tool wear on the workpiece while ensuring extreme pressure performance.

The above is the selection method of common machine tools. In actual cutting, it is necessary to continuously analyze and optimize the workpiece, working conditions, tools, equipment, and other factors to obtain a suitable process with stable workpiece quality and cost-effectiveness.

The Manufacturing Process of Hardware Workpiece Cutting Technology

As people's demand for metal products enters a diversified era, new requirements are put forward for metal cutting technology. When manufacturing hardware workpieces, it is necessary to select and design technologically advanced, economically reasonable, and safe and reliable process plans based on the actual conditions of the factory's equipment and personnel, so that the production of the workpieces can meet the technical requirements outlined in the design drawings.

The following describes the cutting process manufacturing process of hardware workpieces:

- Analyze the drawing of the workpiece: According to the hardware drawings, analyze the shape characteristics, size, precision requirements, raw material size specifications, and mechanical properties of the workpiece. And combined with the available cutting equipment specifications and production batch factors, analyze the cutting process of parts.

- Select cutting blanks: The raw material properties of hardware workpieces directly determine the quality of the finished product. Therefore, the blank should be subjected to strict performance tests before manufacturing, including strength, yield point, tensile strength, elongation, reduction of area, hardness, impact toughness, etc.

- Selection of precision cutting oil: Cutting oil plays a key role in the metal cutting process. Cooling performance and extreme pressure wear resistance have made a qualitative leap in the improvement of workpiece accuracy. Depending on the material of the workpiece, the focus of the performance of the cutting oil is different when it is selected. Usually, the cutting process is determined according to the difficulty of processing, the method of oil supply, and the degreasing conditions.

- The rough cutting process of the work piece: The process of cutting most of the machining allowance from the workpiece blank to make the shape and size close to the requirements of the finished product is a rough machining process. Its processing accuracy is low, and the surface roughness value is large. It is generally used for the final processing of low-demand or non-matching surfaces, and also as a pre-processing for finishing.

- The precision cutting process of the workpiece: The process of cutting away less machining allowance from the rough-machined surface and making the workpiece achieve higher machining accuracy and surface quality is the finishing process. If the surface of the workpiece does not have particularly high requirements, finishing is often used as final processing.

- The finishing process of the workpiece: It cuts a small machining allowance from the surface of the finished workpiece and obtains a high machining accuracy and a small surface roughness value. Grinding, honing, superfinishing and polishing methods belong to the finishing process.

- The heat treatment process of the workpiece: The heat treatment of the workpiece is an important process link in mechanical manufacturing. Generally, the heat treatment does not change the shape of the workpiece and the overall chemical composition, but by changing the internal microstructure of the workpiece, or changing the chemical composition of the surface, it can give or improve the performance of the workpiece. Its characteristic is to improve the internal quality of the workpiece.

The above is the manufacturing process and precautions of the metal workpiece cutting process. Strictly formulating the rules and regulations of each process can effectively avoid the occurrence of quality problems.

How to Choose the Manufacturing Process of Hardware Parts?

The following describes how to choose the manufacturing process of the parts:

-

Process analysis of CNC parts

Numerical control technology analysis involves a wide range of areas, so I only analyze it from the feasibility and simplicity of the numerical control technology.

- Part drawing size and geometric distance: The size on the part drawing should be adapted to the characteristics of the numerical control process, and the size should be quoted on the same basis or given directly. This method not only facilitates programming, but also facilitates mutual coordination between dimensions, and brings great convenience in keeping the benchmark and programming consistent. Nodes must be calculated during manual programming, and all geometric elements constituting the contour of the part must be calculated during automatic programming. Therefore, when analyzing the part drawing, it is necessary to analyze whether the given geometric elements are sufficient.

- The parts meet the characteristics of CNC technology: It is better to adopt uniform geometric types and dimensions for the cavity and shape of the parts. That can reduce the number of tools and tool changes, and improve programming efficiency. The quality of the part process is related to the height of the contour and the radius of the transition arc. The fillet size of the inner groove determines the diameter of the tool, so the fillet radius of the inner groove should not be too small. It is best to have suitable holes in the parts as reference holes to reduce errors caused by clamping. It should also be analyzed whether the required accuracy and size of the parts affect the process arrangement.

-

Determination of the CNC process method

- Selection of process method: The selection principle of the process method is to ensure the requirements of surface accuracy and roughness. Since there are generally many methods to obtain the same level of accuracy, in the actual selection, the shape, size, and heat treatment requirements of the parts must be fully considered.

- Principles of plan determination: The craftsmanship of the more precise surface on the parts is often gradually achieved through rough work, semi-precision, and precision. It is not enough to select the corresponding final method for these surfaces only according to the quality requirements, and the plan from the blank to the final shape should be correctly determined. When determining the plan, first, according to the requirements of the accuracy of the main surface and the surface roughness, the method required to meet these requirements should be initially determined.

-

The CNC process steps are determined

The path of the tool position of the CNC tool relative to the workpiece is called the route. The main principles for determining the process route during programming are as follows:

- The process route should ensure the accuracy and surface roughness of the parts, and the efficiency is high.

- Make a numerical calculation simple to reduce the amount of programming.

- The route should be the shortest, which can reduce the programming section and the time of the empty tool.

-

The selection of high-speed cutting oil

The factors that affect the accuracy of ultra-high-speed cutting generally include cutting standards, the accuracy of cutting tools, the quality of workpiece materials, and the performance of cutting oil. How to choose cutting oil is also an important issue in metal cutting technology.

The above is the classification method of common cutting processes. In actual cutting, it is necessary to continuously analyze and optimize the workpiece, working conditions, tools, equipment, and other factors to obtain a suitable process with stable quality and economic efficiency.