Planetary reducers have been in existence for more than 30 years. During this time, planetary reducers only appeared in high-end equipment in Europe and America. But now, with new trends in automation, planetary reducers have been widely adapted for use in industries including in the machine tool, semiconductor, packaging, medical, food, aerospace, and other industries. High, medium and low power servo motors with planetary reducers have become standard. What are the applications and advantages of planetary reducers? This article will let you know more about planetary reducers.

What is a planetary reducer?

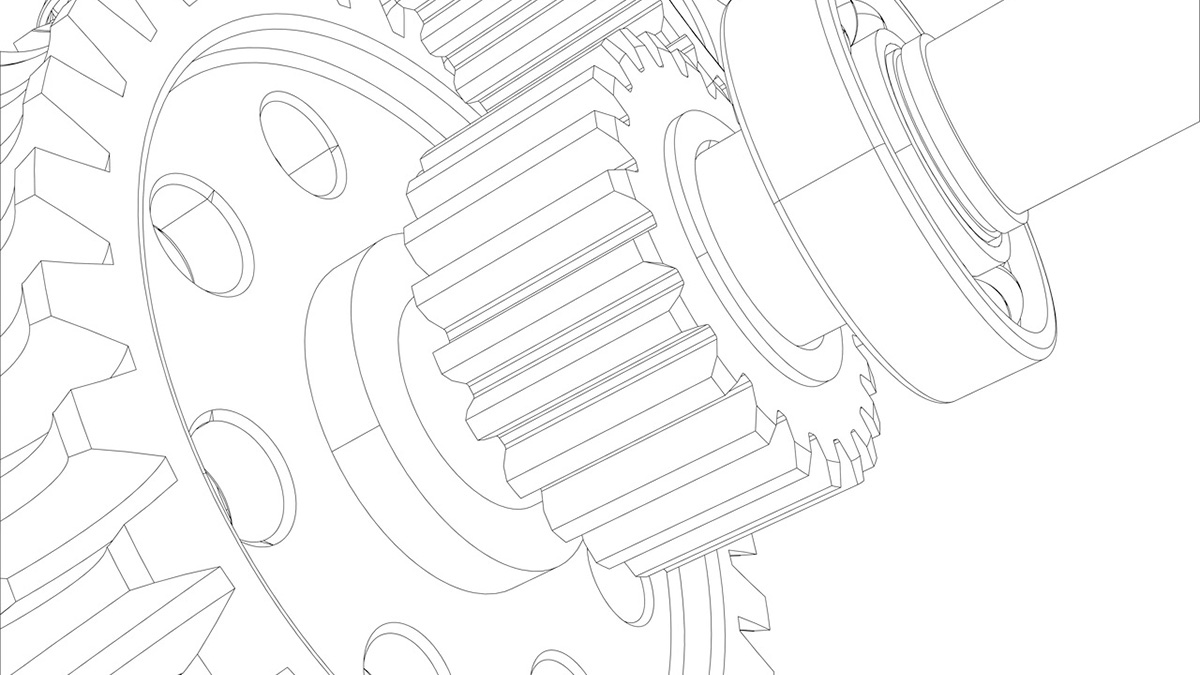

A planetary gear reducer is a type of planetary gearbox that aims to transmit a maximum torque in the most compact form. It decreases the speed of revolutions of a motor and ensures torque. The planetary reducer is composed of a sun gear at the center of the assembly, a ring gear at the outside of the assembly, and planetary gears which contact and rotate between the sun and rings gears. The planetary gears are connected to a planetary arm which. The various gears are arranged so that they rotate at different speeds, and can be used to adjust the input rotation speed and the output rotation speed.

What are the advantages of planetary reducer?

- High torque can be achieved and the torque load can be distributed to different gears. With a small volume, the planetary reducer can withstand higher torque than other reducers.

- Cost savings. With the planetary reducer, the application can use a motor with a low power, greatly reducing the overall cost of the configuration.

- High precision. Most planetary reducers produced today have extremely high precision.

- Low noise. Even larger planetary gears have very low noise levels during operation.

- High efficiency. The loss of power with a planetary gear train is small, so transmission efficiency can reach up to 97%.

- High reduction ratio. Through the combination of multiple stages, higher reduction ratios can be attained.

- Wide range of applications. Due to the high torque potential, high precision, high reduction ratio and compact characteristics of planetary reducers, they have unlimited potential uses in industrial applications.

What are the types and applications of planetary reducers?

After years of development, the planetary reducer currently has the following types:

Output Shaft

The planetary reducer itself has an output shaft which is coaxial or parallel to the input shaft. There are several forms of output shafts to choose from, for example, a common output shaft has a key which allows the reducer and the equipment to be assembled quickly and safely. Optical shafts or bolt-slot shafts allow for configuring with other additional driving parts such as pulleys, gears, sprockets, etc. Planetary reducers are used in machinery and equipment such as machine tools, lathes, milling machines, water jet cutting machines, laser cutting machines, bottle blowing machines, rubber and plastic machinery, packaging machinery, CNC metal processing machines, automatic loading and unloading equipment, automatic doors, robotic arms, and so on.

Flange Type

The output side of the reducer is an output flange designed according to ISO 9409 specifications. Various pinions, pulleys or couplings meet these specifications so they can be easily and quickly connected to the application machinery and equipment. The flange type planetary reducer can provide higher torsional rigidity due to the structural design and the large diameter of the output flange surface. They are especially suitable for applications where the motion direction is constantly changing. They are commonly used in industrial robots with rack and pinion drives.

Right Angle

Right-angle planetary reducers are equipped with a right-angle gearbox which has the output shaft rotating at 90-degrees to the input shaft. This arrangement can save on installation space and make the overall design of the equipment more compact. The output end of the right-angle planetary reducer usually has two types of output shafts and flange types to choose from. They can be installed and used in any direction, which greatly increases their flexibility for installations. They are often used in automatic mechanical devices with servo motors, photoelectric panel handling, automatic storage systems, robotic arms, pipe benders, unmanned guided vehicles (AGV), etc.

In Conclusion

Professional and experienced R&D engineers with flexible manufacturing capabilities are able to develop exclusive planetary reducers for special applications. There are many types of reducers, with different structural designs and transmission methods, and planetary reducers are just one of them. They can be used in countless different fields, and their uses are beyond our imagination.