Knowledge

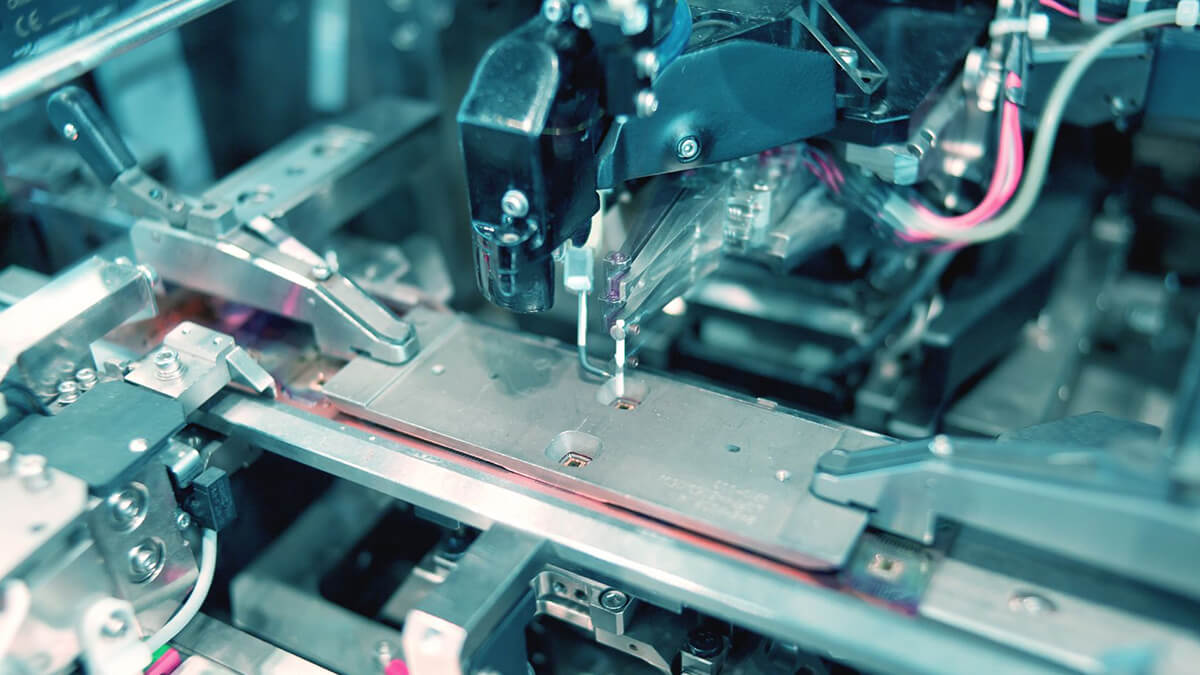

Stamping is a metal shaping process that involves the use of punches and dies to shape thin-walled metal parts.

2023-06-26 13:48:15

It is a metal cutting processing equipment. The rocker arm can be rotated and lifted around the column. The spindle box is a horizontally-moving drilling machine on the rocker arm.

2023-06-26 13:39:15

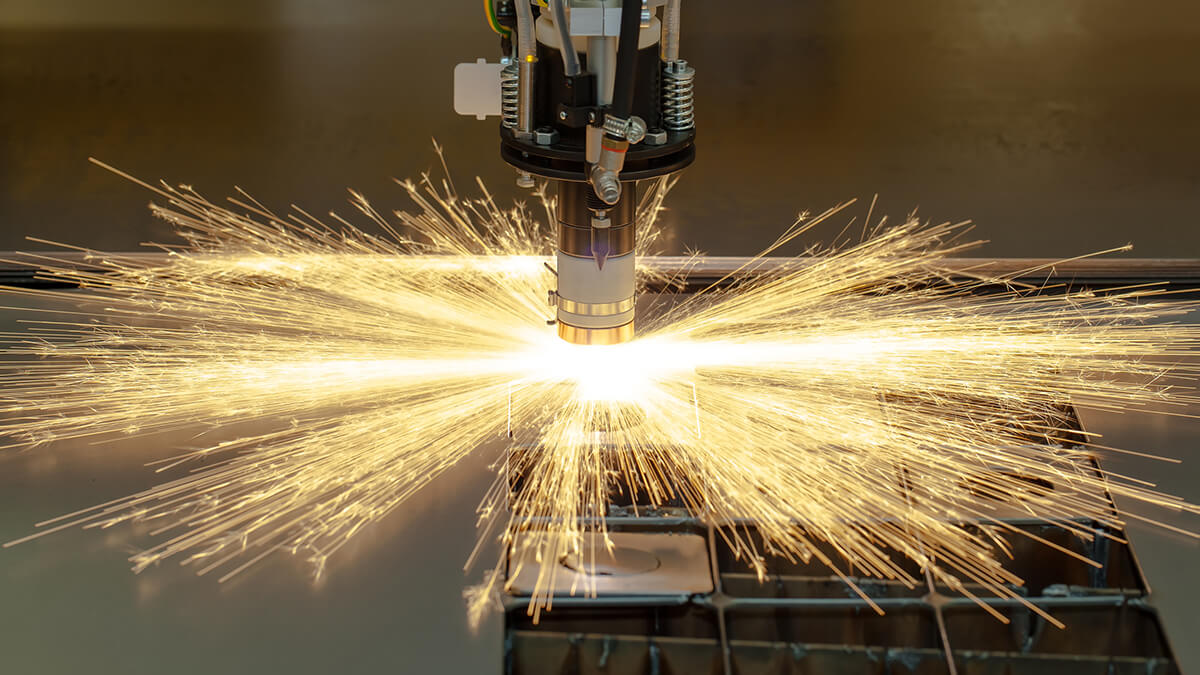

The principle of electrical discharge machining is simply a thermal processing method that converts electrical energy into heat energy of the work piece to quickly melt the work piece.

2023-06-26 13:32:01

The word comes from the English called plate metal. Generally, some metal sheets are plastically deformed by hand or die-stamping to form the desired shape and size and can be further formed by welding or a small amount of mechanical processing to form more complex parts.

2023-06-16 16:11:25

What is a predictive maintenance strategy? In short, it uses the algorithm to analyze and detect the mechanical state before the failure, and predict the time when the failure occurs. In addition to this, it is also possible to determine the type of proactive tasks that can prolong the service life of the machine.

2023-06-16 16:06:29

Flexible production refers to relying on highly flexible manufacturing equipment mainly based on computer numerical control machine tools to realize multi-variety and small-batch production methods. Committed to the goal of zero switching costs, and reduce this waste as much as possible; then the capacity can be adjusted to make it consistent with the market demand capacity.

2023-06-16 16:01:05

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting. There are various grinding machine types, each with a different purpose.

2023-06-16 15:44:05

A shaper is a type of machine tool that uses the linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is analogous to that of a lathe, except that it is (archetypally) linear instead of helical.

2023-06-16 15:37:45

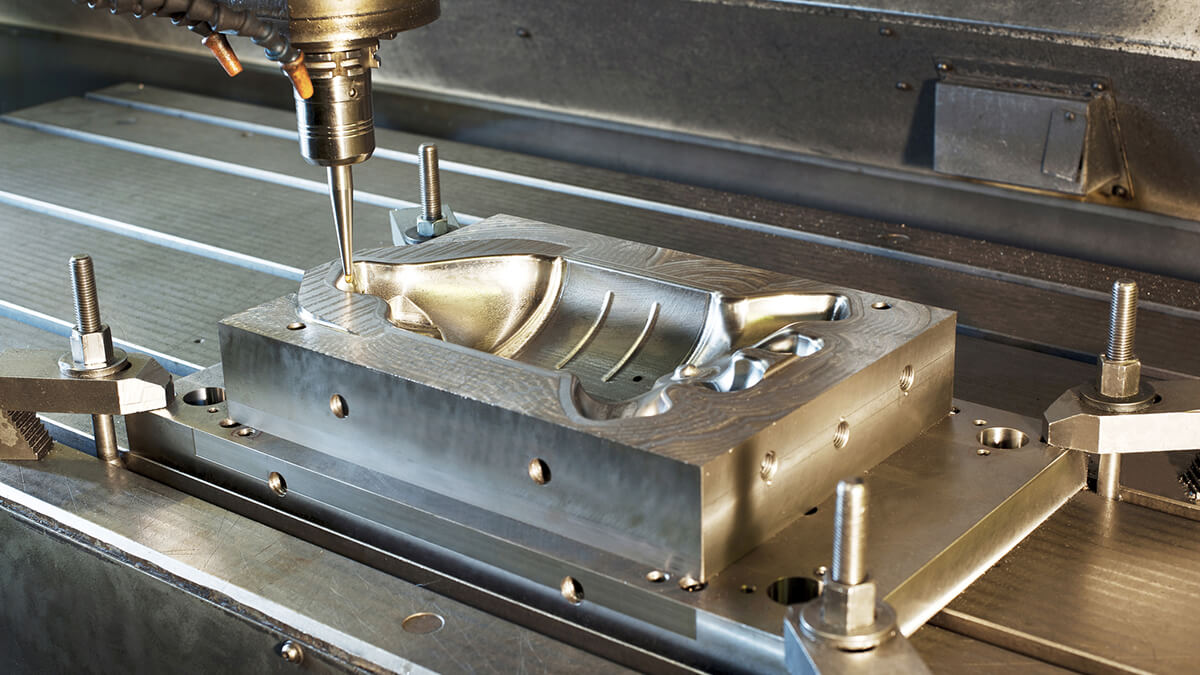

When selecting a milling cutter suitable for the machining task, various issues such as the geometry, size, and work piece material of the parts to be processed must be considered.

2023-06-09 13:51:44

3D printing is a type of additive manufacturing that subverts the thinking of scrap manufacturing in traditional industries.

2023-06-09 13:19:29

Hot Topic

Agree