Knowledge

What is AOI? AOI stands for automatic optical inspection technology, known for its non-contact nature, rapid speed, high precision, and stability. This technology effectively addresses the limitations of manual visual inspection in quality management.

2023-11-17 13:27:02

A shaper is a machine tool that employs the relative linear motion between a workpiece and a single-point cutting tool to shape a linear toolpath. Its cutting process is similar to that of a lathe, but it typically follows a linear, as opposed to a helical, trajectory.

2023-11-07 14:25:45

Shaper machines are intricate pieces of equipment designed for precision machining. They comprise several essential components, each contributing to the machine's overall functionality and effectiveness. To gain a comprehensive understanding of how a shaper machine operates, it's crucial to examine the role and interplay of these individual parts within the complete system.

2023-11-07 14:16:03

Let's explore the definitions of planers and shapers. Planers and shapers are both machine tool applications frequently found in the machine tool industry.

2023-11-07 14:08:10

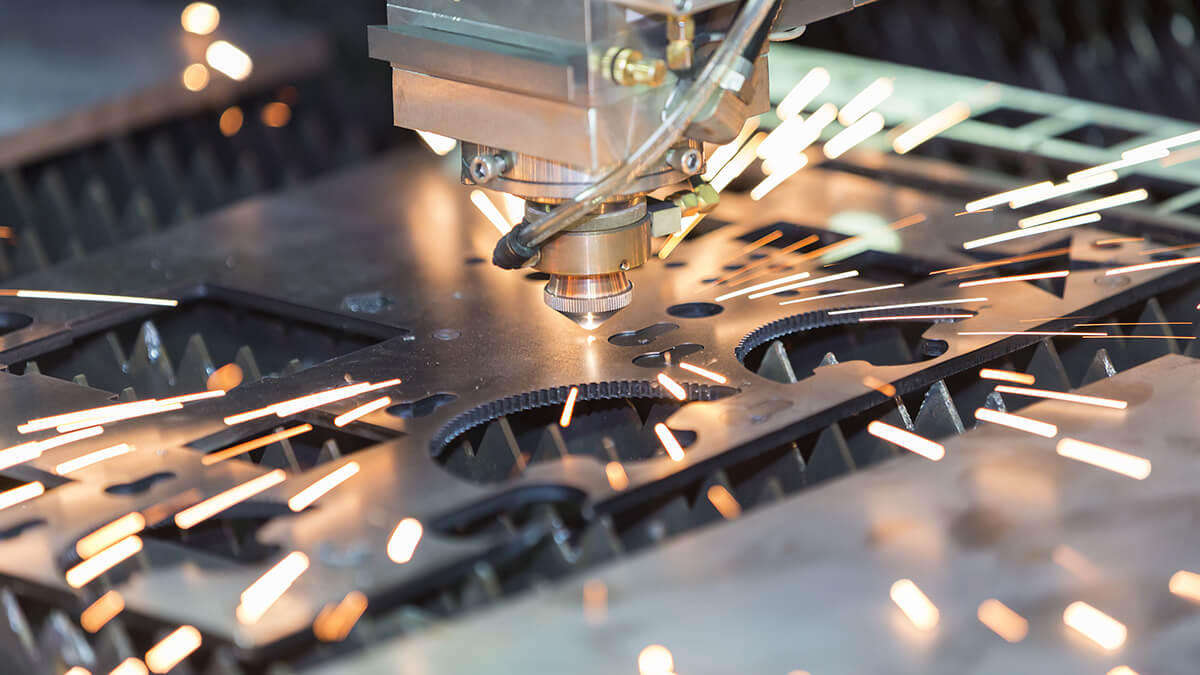

When comparing laser cutting technology to traditional cutting methods, laser cutting offers superior precision, as it utilizes a high-intensity laser beam to cut through materials with exceptional accuracy, even for intricate details.

2023-11-07 13:59:00

Cutting technology encompasses various processing methods, with laser cutting being capable of fulfilling intricate and highly precise cutting demands. It is a prevalent technique widely used in industrial manufacturing.

2023-11-07 13:34:10

Defects are bound to occur during the reprocessing of mechanical equipment or metal parts. As a result, the final step of surface treatment holds significant importance. It serves the dual purpose of enhancing the aesthetics and protecting the surface, ultimately improving the performance of metal components and preventing rust.

2023-11-03 14:08:28

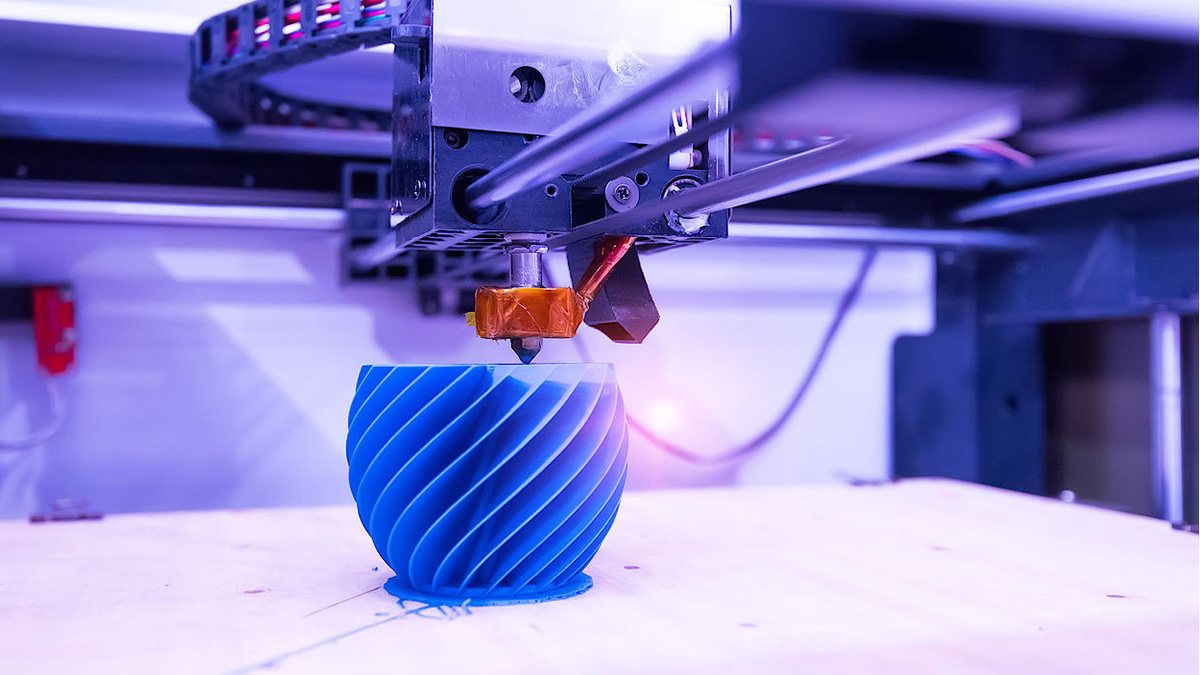

The worldwide manufacturing sector is shifting toward smart manufacturing, with Industry 4.0 leading the way by promoting greater efficiency, reduced costs, and intelligent, adaptable production processes. The nine key technologies of Industry 4.0 encompass Big Data, Layered Manufacturing, Cloud Technology, Automation, System Integration, Internet of Things, Cybersecurity, Augmented Reality, and Simulation.

2023-11-03 13:57:30

In most cases, blackening treatment on steel, also known as black oxidation, can enhance corrosion resistance to a certain extent. However, the protective effect remains somewhat limited. To significantly improve both corrosion resistance and lubrication of the blackened layer, additional measures like oil immersion or subsequent rust prevention treatment are still necessary.

2023-11-03 13:33:55

Anodization is a surface treatment process, typically performed as the final step in metal manufacturing. It is a dependable and cost-effective method for enhancing wear resistance and adding color to precision machined metal parts, particularly aluminum and other non-ferrous metals.

2023-11-03 13:25:22

Hot Topic

Agree